What are I-Beam Jib Cranes?

I-Beam Jib cranes exist in multiple configurations to support a variety of applications. Examples of workplaces that use jib cranes include warehouses, military facilities, equipment manufacturers, and order fulfillment providers. In general, jib cranes are categorized according to their mounting configurations: Free Standing, Floor Supported, and Wall Mounted.

Why Gorbel's I-Beam Jibs?

As a safety manager or plant operator, you would likely agree that two of your top goals are to maximize productivity and promote workplace safety. One of the best ways to achieve these goals is to install one or more jib cranes at your facility. In addition to helping your team increase their product loading and unloading efficiency, jib cranes can be used in many different types of applications. Most importantly, they can help you reduce lifting injuries and minimize downtime.

Free Standing Jib Crane

As the most widely used type of jib crane, a free Standing jib crane is manually operated and is able to rotate 360°. They are manufactured in a wide array of heights and spans and require a 6” reinforced concrete foundation for secure mounting.

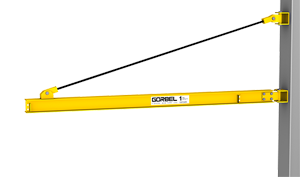

Wall Bracket Jib Crane

Wall Bracket Jib Cranes are the most economical means of providing hoist coverage for individual use in bays, along walls or columns of plants, or as a supplement to an overhead crane or monorail system. They offer 200° of rotation.

Wall Cantilever Jib Crane

Wall Cantilever Jib Cranes have the advantage of providing maximum lift for the hoist, since it can be installed very close to the underside of the lowest ceiling obstruction. They offer 200° of rotation.

Mast Type Jib Crane

The Mast Type Jib Crane is floor supported, top stabilized, and is capable of 360° of rotation via a top and bottom bearing assembly. It usually requires no special foundation which makes it the most cost effective of the 360° rotation jib styles.