In the fast-paced world of industrial innovation, very rarely do we look to the past. When we do, it’s to celebrate our people and especially how our technology has Improved Lives.

| We invite you to join Gorbel® in celebrating the 25th anniversary of the G-Force® Intelligent Lifting Device. From its visionary beginnings in the early 1990s to a groundbreaking launch in 2000, this remarkable piece of engineering revolutionized the way we lift and move heavy loads in demanding work environments. Even today, the G-Force® remains a leading material handling solution that is positioned to continue evolving with the industry. |

The Visionaries Behind the Venture

The origin story of the G-Force® is best told by David Butwid, one of the company’s earliest employees. David joined the Gorbel® team in 1980, just three years after our founding. “My role was Product Marketing Manager, and it was one of those things where the title was deceptive” he recalled with laughter, “I did customer service, purchasing, lots of different things.” David’s responsibilities grew overtime and by the late 1980s, he was appointed General Manager.

Meanwhile, Mechanical Engineering professor and roboticist Dr. Homayoon Kazerooni was working on his latest invention – the Intelligent Assist Device. “My primary motivation was to reduce the risk of work-related injuries,” Dr. Kazerooni told us. His devices essentially comprised of a servo motor with a mounted pulley that connected to a wire rope and handle. It was far from an industrial machine, but it was unique in its responsiveness and function.

What happened next would forever change the careers of these two men and ultimately shape the Gorbel® legacy: | -and-dr-homayoon-kazerooni-(r).png?sfvrsn=d9f3e719_1) Recent portraits of (L) David Butwid, Former Gorbel® Vice President of Sales and (R) Dr. Homayoon Kazerooni, Professor of Mechanical Engineering at UC Berkeley. |

“In the early 1990s, Dave Reh [Founder of Gorbel®] was on the Board of MHI and they needed somebody to support a four-day event in France. A research symposium. All of a sudden, I got a tap on the shoulder from Dave Reh. He couldn’t go. So, I hopped on a plane. I wasn’t a guy who was into research, but someone there told me to go to see this presentation on Intelligent Assist Devices. I knew when I saw it… Dr. Kazerooni had something… I was never an engineer, but I was a dreamer.”

David Butwid, Gorbel® Retiree and Former Vice President of Sales

Inspired by what he saw, David approached Dr. Kazerooni after the presentation. They spoke about the many challenges in the material handling industry and quickly realized how well-aligned their business interests were. Many phone calls and a few months later, negotiations started. Richly described as tough by some and smooth by others, the negotiations eventually solidified into a licensing deal. The groundwork for a state-of-the-art lifting product was now in place.

From Prototype to Product

The task ahead was monumental – transform Dr. Kazerooni’s Intelligent Assist Device into a commercialized product. This process would take the better half of the 1990s and started with a prototype that resembled an electric chain hoist. “We blew apart the first prototype in a short period of time,” David said with a bit of humor. Too much stress on the wire rope was compromising durability. Realizing it would never last in a high-cycle environment, David handed the project over to the engineers.

The “Shoebox” prototype, which incorporated streamlined controls.

Mike Taylor was in the early stages of his Gorbel® career when he was brought onto the G-Force® project. In his then-role as Engineering Manager, he helped develop the G-Force® from prototype to product. “The early prototypes were very rough and they all had nicknames,” he recalled. “My two favorites were the ‘Shoebox’ and the ‘Bowling Bag.’” The Shoebox was the first prototype that underwent advanced programming and control conceptualization in collaboration with Industrial Indexing Systems – a fellow Victor, NY business located on the same road as Gorbel® headquarters.

The controls of the G-Force® proved to be one of the most important aspects of the device. When the first commercialized G-Force® was launched in 2000, its controls were festooned from a panel to the actuator. By 2002, an improved version fully integrated the controls into the actuator. Mark Grandusky, Gorbel® Product Sales Manager, worked closely with engineers like Mike and became a major face associated with the product. In the early days of promotion, those pesky controls stuck out to him, “Whenever they got moved around too much or had to be shipped somewhere for a demo, the chassis of the enclosure would flex and eject all the circuit cards. I spent a lot of time putting those back together back in those early days.”

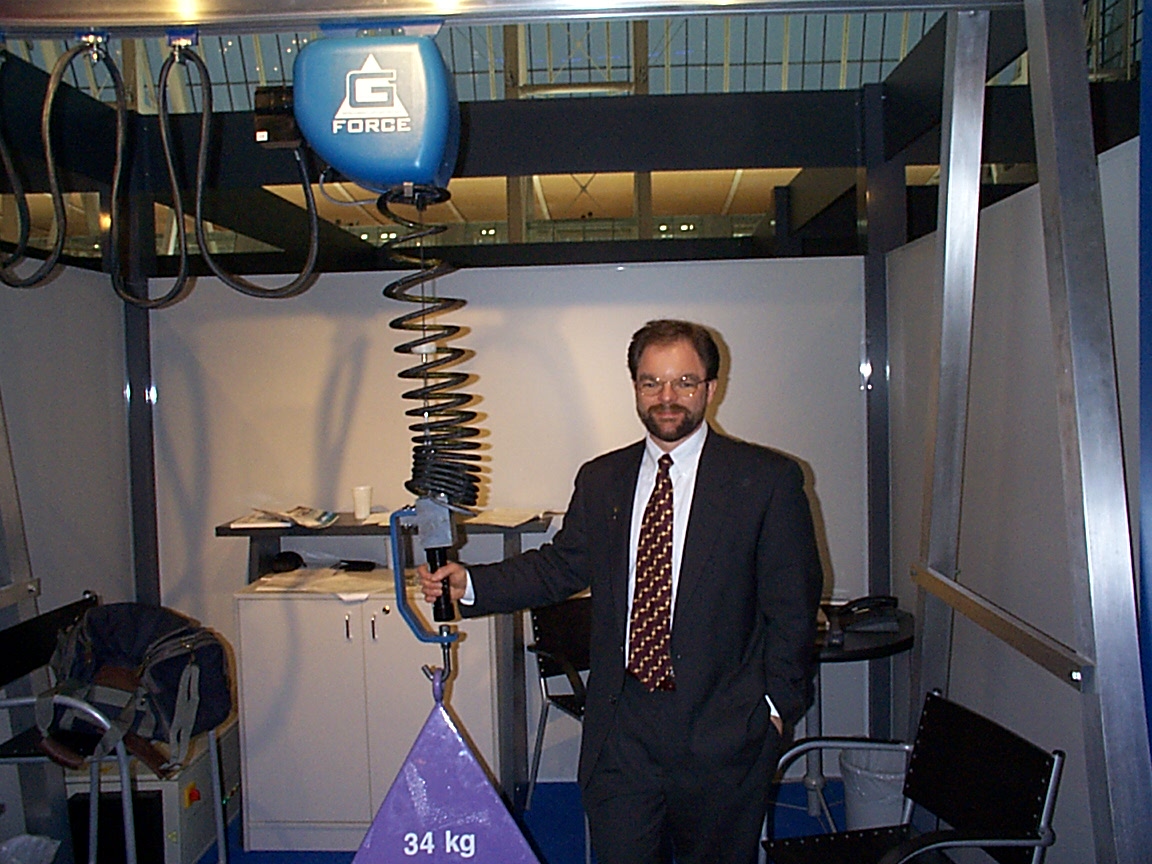

Mark Grandusky. Gorbel® Product Sales Manager, exhibits the “Bowling Bag” version of the G-Force® and encourages potential customers to demo the product.

Another early improvement to the commercialized G-Force® device was the creation and engineering of Float Mode, which allows operators to precisely move loads through a natural range of motion with just a 1/2lb of force. For many, the best way to understand Float Mode is to experience it. Offering demos in abundance was key to marketing the G-Force® in the early days. Mark explained, “As with any innovative technology, there’s always a few, brave early adopters that are instrumental in gaining a foothold in the market.” By 2010, the the G-Force® was beyond the early adopter phase and had earned a reputation for increasing efficiency while reducing workplace injuries.

From the Past to the Future

We have come a long way since the days of ejected circuit boards and awkward festooning. Today, the G-Force® Intelligent Lifting Device is a world leader in servo powered technology. Latest models can lift more than 1,000lbs and have even become the backbone of our Easy Arm™ articulating jib system. As you read this, G-Force® devices are lifting almost anything you can imagine – from farm equipment to space rovers. And while we are proud to celebrate this achievement, David Butwid said it best, “If there’s anything grand about this, it’s how the G-Force® improved workplace safety.”

So let’s fix our gaze once again to the future; join us in discovering it.

Want to experience the G-Force® for yourself?